Solid, Granular & powdered materials are usually handled by mechanical Bentonite conveying system tools such as belt conveyers/Bentonite Conveying systems /bucket elevators/ screw conveyors/goods lifts, etc.

This latest vision is making the solids airborne, in a liquid condition, with the use of air or unusable gas transiting in a sealed pipeline. The idea was found very enchanting due to the closed pipeline Bentonite conveying system it was selected by most industries for handling the solids inflatable in the last three (3) decades.

Relyed on the product's features like volume, air pressures are used for the setup stage. These parameters categorize the systems as either DILUTE / LEAN Phase Conveying System or Bentonite Conveying System.

As a supreme manufacturer of Bentonite Conveying Systems in India, we are using current technology for manufacturing Bentonite Conveying Systems in Ahmedabad city – the business junction of Gujarat. When it's come to high-quality Bentonite Conveying Systems in Gujarat, TECHFLOW is one of the most trusted and reliable names.

Discover moreTECHFLOW is one of the frontiers manufactories of Bentonite Conveying Systems. The Bentonite Conveying System is more conceived for Pneumatic Transporters, material transporter, and Foundry Sand Transporter. This conveying system is used to convey the material from the source to numerous or single destinations with the help of collective air. These processes employ higher force with lesser air volume per kilogram of weight conveyed compared to the LEAN phase system. Solids in powder form are more significant total inability as same as related with this type of conveying system. The pipeline mostly has a thicker solid component flowing in the air, thus termed Bentonite.

Bentonite Conveying Systems are more classified as PLUG TYPE & CONTINUOUS TYPE, as per the motion of the solid style in the pipe.

Medium to high forces needs for this kind of Bentonite Conveying system, so dry compressed air is engaged as the prime moving force.

Bentonite Conveying system speeds are designed somewhat lower & under 5 meters/sec. Yet, starting forces sometimes overreach 3 to 4 Bar developed equivalent with the distances to be transmitted & system resistance. The pipe diameters are developed according to the resulting requirement & and work out somewhat smaller.

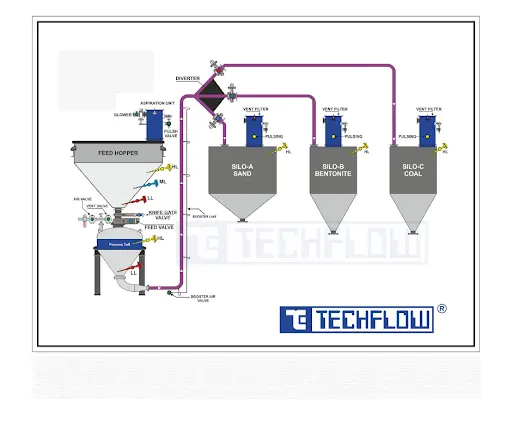

A pressure vessel is kept to obtain & transport the powder material. A terminal pulse-jet filter is kept to duct the bentonite conveying system air. A pack of compressed air valves & sensor systems mostly come assembled in the vessel. A prior storage feed hopper is held above the Vessel with an isolating Dome Tuff in between. An electrical control panel with a PLC schedule is provided to manage the cycles of FILLING & CONVEYING.

The following 2 types of Bentonite Conveying Systems are supplied by TECHFLOW

High-quality Bentonite Conveying Systems are manufactured in Ahmedabad. As an outcome of our prime focus on quality, we are one of the best manufacturers of Bentonite Conveying Systems in Gujarat. Over the years. TECHFLOW stands as the most trustworthy manufacturer of Bentonite Conveying Systems in India.

The Bentonite conveying system for the dense phase has achieved popularity as it is an adequate system to move hard, abrasive, and brittle materials at a slow speed. It drives material along an enclosed pipe, in a plug form, using a small volume of gas, at a lower velocity but medium and increased pressure Bentonite conveying systems have a rare wearing part that contributes to the tiniest maintenance. Also, the production costs benefit as there is low material degradation, especially when Bentonite conveying system delicate materials. Techflow is a leading manufacturer of pneumatic conveying systems for the dense phase in India, which gives the grade-engineered equipment and is in rising demand across the industry.

| Bentonite Conveying System Application | ||||

|---|---|---|---|---|

|

|

|

|

|

| Bentonite Conveying System Options | |||

|---|---|---|---|

|

|||